Biocircular

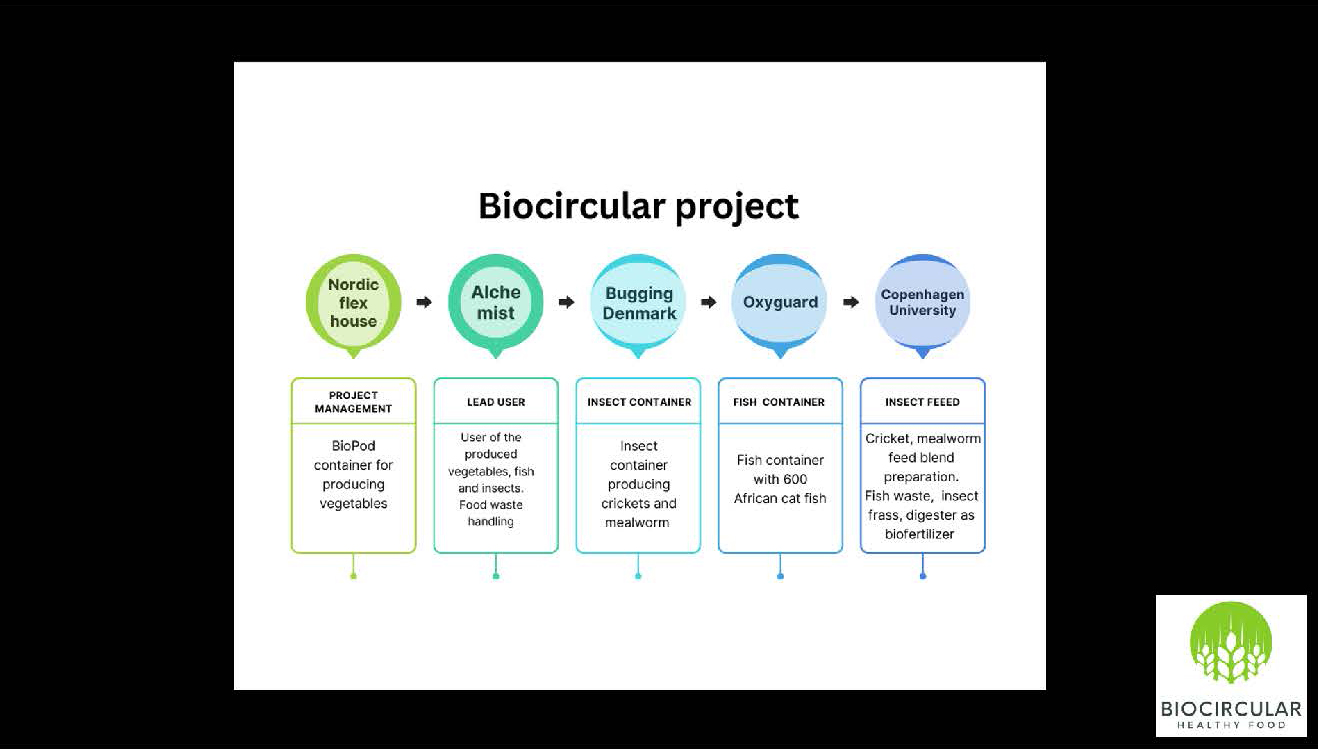

Nordicflexhouse has won a GUDP project together with Alchemist Restaurant, Bugging Denmark, Copenhagen University and Water ApS (OxyGuard).

Purpose

Nordicflexhouse has won a GUDP project together with Alchemist Restaurant, Bugging Denmark, Copenhagen University and Water ApS (OxyGuard). | Nordic Flex House

Project Team

The project partners are:

BioPod container in Alchemist

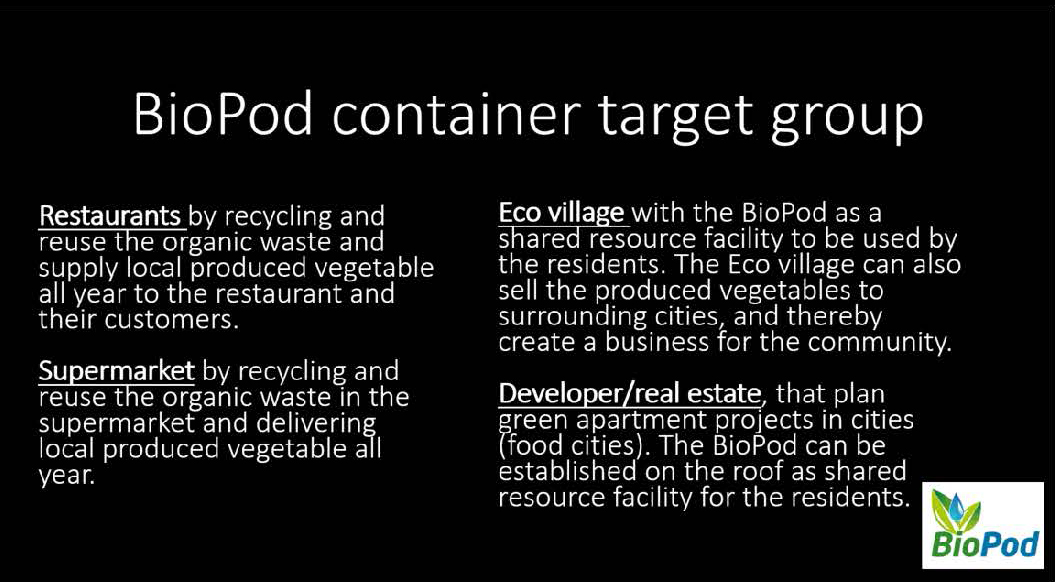

The target group of the Biocircular containers are outlined in the figure below.

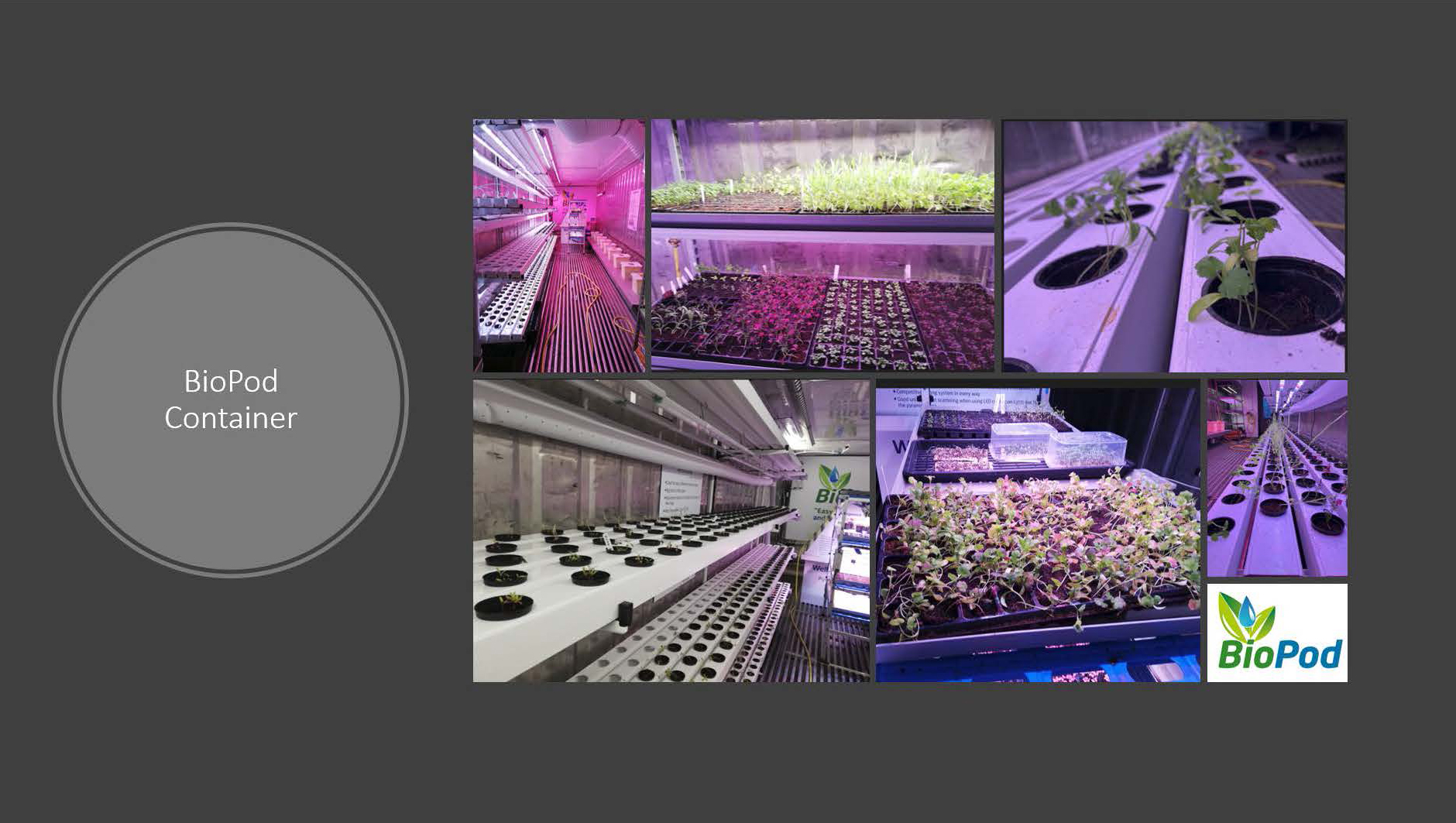

The BioPod container has been optimized for the Alchemist demonstration project, so more growth tables have been installed as shown in the figure below.

There is integration between the BioPod container and the fish container regarding CO2, O2 and fish rich water. Fish container generate CO2, that will be send to the BioPod container to be used for the crops production. The BioPod container will send O2 to the fish container, that need it for the fish production.

The following data is important between the containers:

- Temperature, air humidity, air flow.

- Fishing sludge (liquid and solid fertilizers). About 20 liter of fish rich liquid water will every 3 day be send from the fish container to the BioPod container water tank. The tank will through a water pump deliver sludge water to the dripping system of the different crops. In the BioPod container we will analyze the composition of fertilizers in the sludge tank.

- Fish sludge (solid), insect frass and digester from the Copenhagen Municipality organic biogas plant will be used in the BioPod container as nutrient to the crops. The solid part will be used in the Dutch bucket and the digester fluid water will be send to the water tank of the BioPod container for testing.

- The protein, fat and carbohydrate of the insects (worm and cricket) to be used as feed to the fish. It is important information for Oxyguard to determine the insect value as feed to the fish.

Digital solution in the BioPod container for Alchemist project

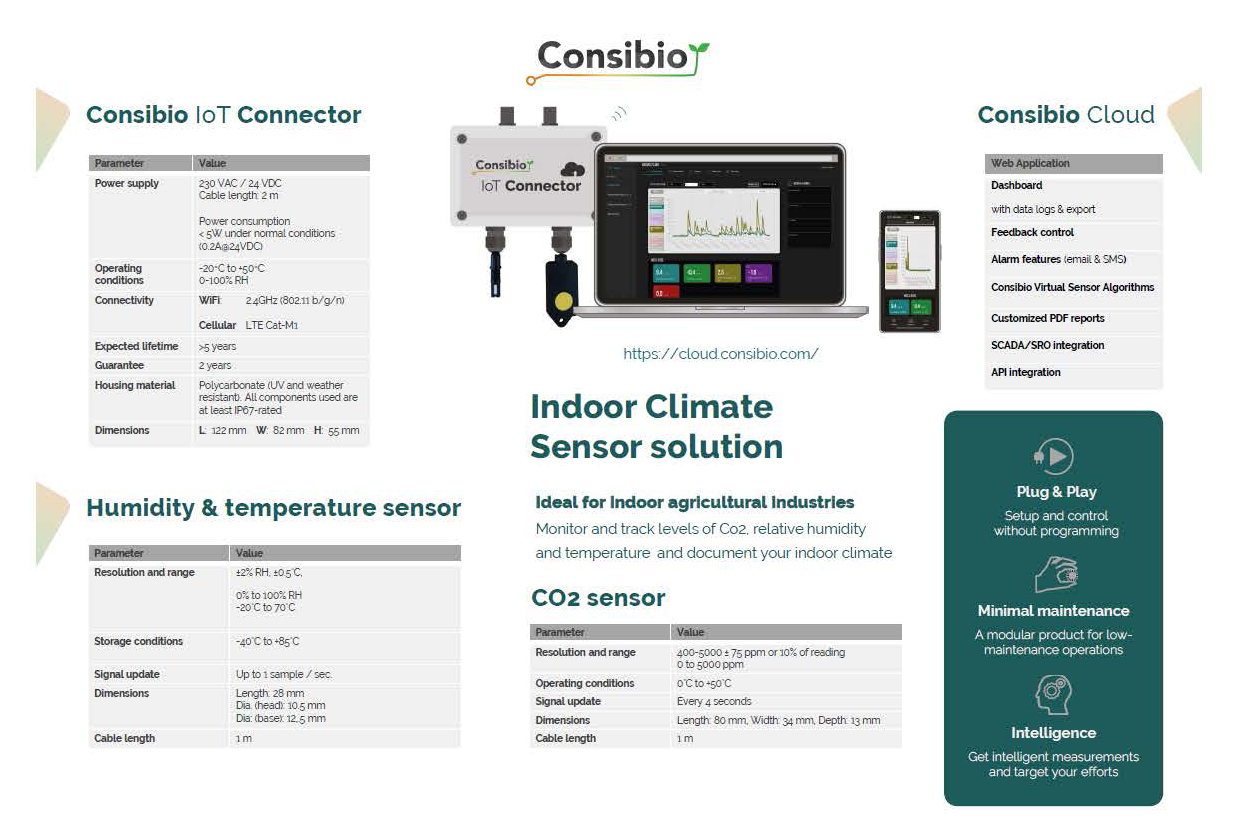

The Consibio Cloud Platform is where the BioPod digital solution is configured.

Consibio will deliver Consibio IoT Connectors to the BioPod container, including sensors and gateway, so that it will be possible to monitor indoor temperature, humidity, CO2, water quality (PH, EC, temperature).

Consibio will develop an algorithm to that there will be online CO2 measures of the Biocircular containers. CO2e will be generated from Consibio Cloud on a daily basis across the three Biocircular containers.

See overview of the Climate Consibio IOT and Cloud for this project.

Dynamic BIM of the BioPod container

We will create a BIM model of the BioPod container shown as a walking through video.

Fish container in Alchemist

The Biocircular fish container produces fish for consumption and nutrient rich water and sediment for use in the Biopod container for vegetable production. Insects (crickets or mealworm, produced by Bugging) mixed with regular fish feed will be used as feed for the fish. The container is a 40-foot container and will be a unit located between the Biopod plant container and the Bugging insect farm. Although the production is flexible in terms of species produced, the production will initially be of African sharp-tooth catfish (Clarias gariepinus, Figure 1) approximately 500 kg / year as startup (higher production is possible if required later).

Figure 1. African sharp-tooth catfish (Clarias gariepinus).

The system will be mostly automatized, with the only on-site maintenance being re-filling the automatic feeding system and collecting nutrient-rich sediment from a settling tank. The setup will be online, monitored by sensors and camera, connected to the OxyGuard Pacific / Cobalia system, making it remotely operational in regards to oxygen concentration in water, feeding, water treatment, etc.

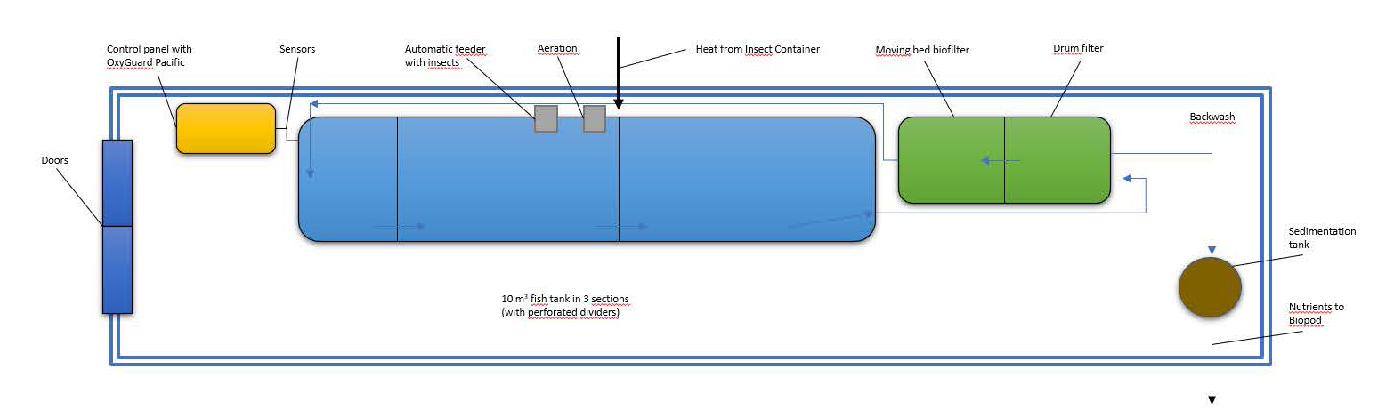

The fish container is equipped with a fish tank with 3 compartments with feeders, aeration units, drum filters, biofilters and a sedimentation tank. Several sensors are monitoring the water quality parameters and are connected to OxyGuard’s Pacific and Cobalia system (Figure 2).

Figure 2. Draft of fish container. From left to right:Pacific control unit(+ sensors), 3-chambered 10 m3 fish tank with feeders, aeration, with inlet and outlet to the treatment unit (drum filter + moving bed biofilter), sedimentation tank.

The fish tank will be a 10 m3 tank with 3 chambers (4 m3 + 4 m3 + 2 m3), which makes it possible to run feed / growth trials and having 1 smaller pre-grow out chamber for smaller fish (Figure 3). The

temperature of the container is regulated via connections to both the Biopod and the Insect container, with an optimal temperature of 27 °C ± 5 (C. gariepinus).

Mineralization of ammonia and nitrite into nitrate, suitable for the Biopod plants, will occur in the moving bed biofilter inside the container. Solids in the water are removed by the drum filter, which will then be concentrated in the sedimentation tank.

The tank will deliver sludge and enriched with nutrients water to the fertilizer mixer of the BioPod container and then they will be sent to the dripping system of the different crops. In the BioPod container they will analyze the composition of fertilizers in the sludge tank.

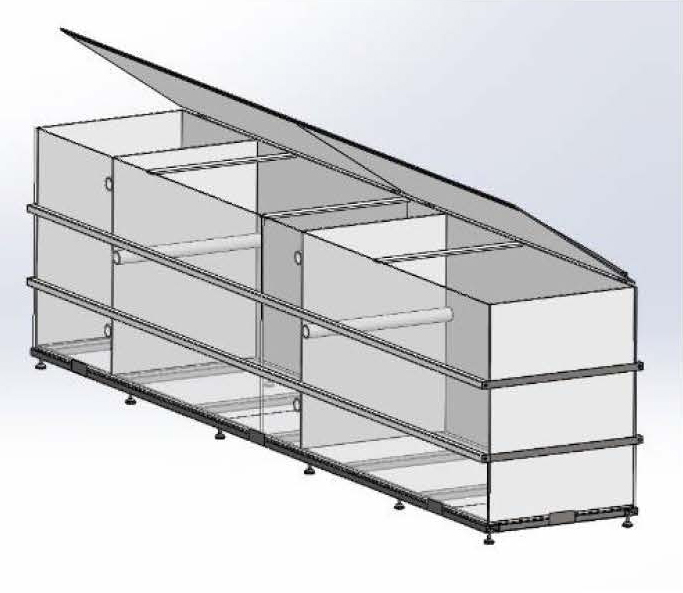

Figure 3. Technical drawing of 10 m3PE fish tankwith 3 chambers.

Below are illustration of the fish container key functions.

Figure 4. Schematic of 40-foot fish container.

Fish container will have high humidity. This humidity air will be sent to the insect container, that needs this humid air in their container. Fish container also generate CO2, that will be sent to the BioPod container.

Digital solution

The fish container will be equipped with OxyGuard Pacific control unit which will collect data from the various submerging sensors in water to ensure optimal growth of the fish. Pacific will be connected to OxyGuard’s cloud system Cobalia. Regarding the climate monitoring, Consibio Cloud Platform will also be used in the fish container to monitor temperature, humidity and CO2-levels.

The climate regulation units, which contain various sensors will be used to control environmental parameters.

Dynamic BIM

Dynamic BIM of the fish container. See video of the fish container: Biopod Container | Nordic Flex House.

Insect container in Alchemist

The BIOCIRCULAR insect farm is a modular production unit for the production of edible insects. The farm is the first unit in the BIOCIRCULAR production system. The input is foodwaste side-streams and the output is insects (crickets or mealworm), which can be used as feed in the fish container or they can be used directly for human consumption.

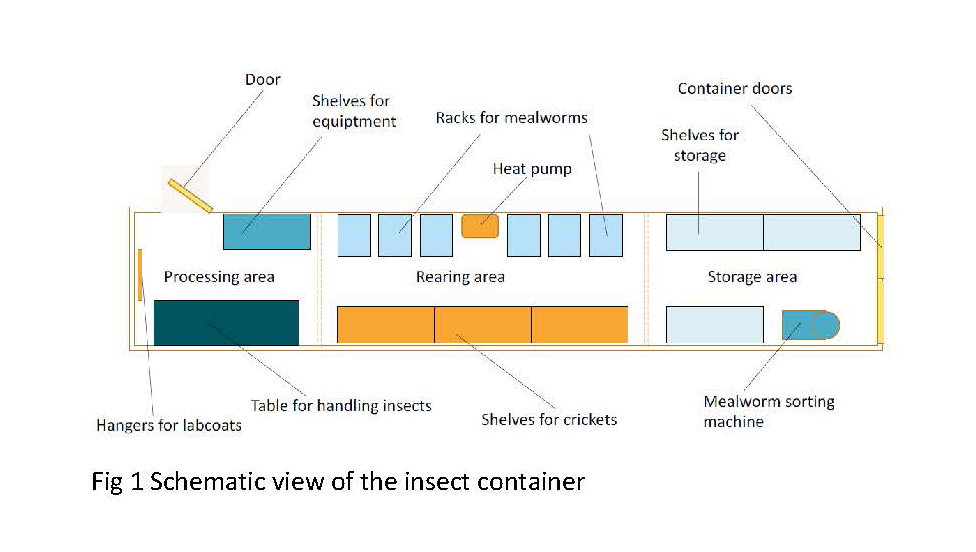

The BIOCIRCULAR insect farm container is constructed in an up-cycled 40-foot container and is able to accommodate several different species of insects (e.g. crickets and mealworms). The container has separate areas for rearing and processing as well as storage space. It is equipped with climate control units including an air-to-air heat pump, ventilation (controlled by a CO2-sensor) and humidity control.

The insect container will be tested for house crickets (Acheta domesticus) and mealworms (Tenebrio molitor). Initially the demonstration farm will be set up to produce both and can later be fitted to produce only a single (see floor plan below). Under optimal conditions, yield of mealworms is estimated at 1025 kgs and cricket yield at 600 kgs. However, since crickets and mealworms have their respective optimal growth rates at different temperatures, growth rates will depend on which temperature is chosen for the container microclimate at any given time. Also, volumes will depend on feed conversion ratios (FCR) of the various sidestream used as feed, since lower FCR can result in lower growth rates and higher mortality. The flexibility of the container setup (in terms of insect rearing units, temperature and humidity) should allow for other species of insect to potentially be reared as well.

Fig 1 Schematic view of the insect container.

Digital solution

The container will adapt the Consibio Monesco system for climate monitoring. The system will monitor temperature, humidity and CO2-levels. The climate regulation units each contain individual sensors which will be used to control the environmental parameters. The Monesco system will (initially) only be used for monitoring climate, not controlling it.